Specifically designed for non-destructive testing, ensuring precise detection without omission.

Versatile Applications: Widely used in industrial leak detection, cleanroom inspection, and more, meeting diverse industry needs.

Non-Destructive Testing(NDT)

NDT Testing For A Variety Of Applications

Ultraviolet light can be used to test the fluorescent reaction of wall marks, pipe cracks and automobile parts.

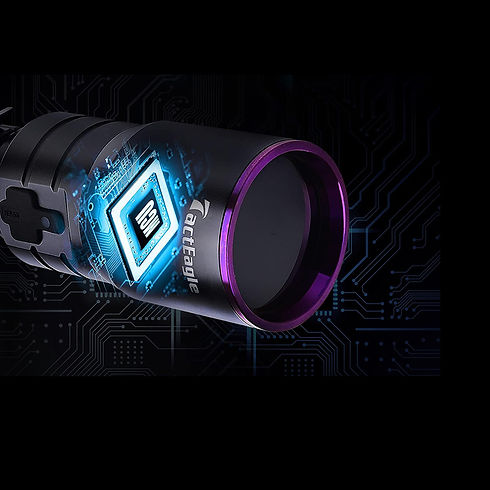

TACTEAGLE MCU INTELLIGENT CONTROL CHIP

Optical Instruments: Used for curing, cleaning, and circuit node operations.

Electronics Manufacturing: Suitable for curing circuit nodes and other operations.

Oil and Gas Industry: Used for leak detection to ensure pipeline safety.

Power Plants: Assists in various inspections at power plants.

UV Adhesives and Inks: Used for curing operations.

Mining Industry: Suitable for fluorescence reaction detection.

Aerospace/Automotive/Maritime Sectors: Used for flaw detection operations.

PERFECT FOR FLUORESCENT PENETRANT INSPECTIONS

Stable Light Source: The TactEagle UV flashlight provides a steady and reliable light output, ensuring consistent performance during inspections.

Meets NDT Testing Standards: Specifically designed to emit a light intensity that satisfies the stringent requirements of non-destructive testing (NDT), making it an ideal tool for professionals in the field.

Enhanced Fluorescence Detection: With its 365nm wavelength, the flashlight enhances the visibility of fluorescent penetrants, allowing for precise detection of flaws and defects.

UV FLASHLIGHT APPLICATIONS

NDT Professionals: Essential for those conducting non-destructive testing, providing reliable and accurate results.

Quality Assurance Teams: Ensures product integrity through thorough inspections.

Industrial Maintenance: Facilitates effective maintenance checks in various industrial environments.

UV FLASHLIGHT TARGET CUSTOMERS

Safety Inspectors: Helps identify potential hazards and defects with a stable and strong UV light source.

Engineering and Technical Staff: A valuable tool for detailed material inspections and analyses, ensuring all inspections meet the highest standards of accuracy.